Refrigerator Repair Screts For All Interruption Of Damage

Steps Repair 1 - 2 Doors Refrigerator With Easy

How to fix the refrigerator is basically the same even though its brand LG SHARP SAMSUNG TOSHIBA SANYO PANASONIC POLYTRON or other brands, only the location and shape of components slightly different but sometimes the same form, function and how it works.

An easy way to determine the cause of damage should my friend must know the characteristics of damage to the refrigerator, whether the refrigerator is totally dead, the refrigerator does not want to cool, the refrigerator is less cold.

On this occasion I will tell "Secrets To Repair Refrigerator For All Damage Disorders" on the 1 door or 2 door refrigerator, both electrical component system and refrigrent gas line system repair.

Immediately I explain one by one way to overcome the refrigerator damage 1 door and 2 doors. Before fixing the refrigerator should first check the electrical home, who knows the cause of the problematic refrigerator is actually due to saggy plugs, Voltage is not stable electricity or because not yet buy token pulses electricity.

How To Fix The Refrigerator 1 Door Off Total

The meaning of total death does not mean the lights are also dead, if the damage occurred together with the refrigerator lights off the possibility of the cause of the cable is loose or broken bitten rats.Total dead refrigerator damage here is a compressor machine as its heart refrigerator does not want to pump freon gas (refrigrant) located behind the refrigerator is not working, no sound, no heat and no vibration.

How to find damaged refrigerator die in the following way:

The first step

Check the 2 cables leading to the compressor machine, if you have multi tools can be measured by knowing whether the two plug wires are connected to the cable path leading to the compressor engine.

If one of the cables is not connected to the power outlet means damage to the thermostat, replace with a new thermostat.

Changing the new thermostat is not necessarily a suitable temperature setting, sometimes freezer temperature has not been frozen, thermostat has cut off the electrical current to the compressor machine.

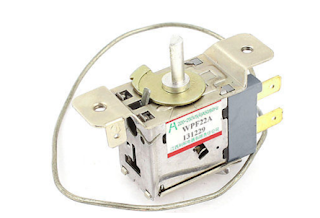

|

| Refrigerator Temperature control - Thermostat |

Step two

Overload is a safety coil motor compressor that will automatically cut off the electrical current in the event of damage due to the winding is broken, the voltage drops or unstable voltage, compressor engine is stuck or due to excess engine heat and will be connected again when the heat decreases.

|

| overload motor compressor |

Overload is mostly damaged by age or cracked (broken).

Third step

Check PTC Relay that works to connect atara coil running and starting.

|

| PTC Relay engine compressor |

Damage to the PTC Relay is common due to ceramic heater as a broken link, but usually characteristic of damage marked compressor machine if held warm or hot feeling due to failed restart.

Checking PTC Relay does not hurt, who knows not connected to pin running due to corrosive or rusty. When the Overload and Refrigerator PTC Relay conditions are in good condition, it means the damage due to motor coil compressor break (replace the new compressor machine).

How to Fix a Refrigerator 1 Door Less Cool

Fix a one-door refrigerator in this case the compressor engine is vibrating but less cold and where the freezer shelf is not found ice or there is only partial flower above the freezer or the margin of possibility due to freon gas leak, there is deadlock filter and capillary pipe or pipe line evaporator oil buildup occurs.But it could also refrigerator less cold due to pressure / compression pumpa compressor machine is not strong.

For a 1-door refrigerator it is less cold but there is an icy flower or a flowering of evenly distributed ice flower throughout the freezer rack because the refrigerator door is not tightly closed.

How To Repair the Refrigerator 2 Door Off

To detect the damage of the two-door refrigerator completely dead the compressor engine is not alive, no sound, no vibration or heat and the fan blower in the freezer room is also dead but the lights can still live can do the following steps.The first step

Find the location of the refrigerator timer, where most of the refrigerator timers are behind the refrigerator on the left-hand corner, but there is a refrigerator type that is placed inside the bottom door chamber.

|

| Place the timer behind the refrigerator |

Is the condenser pipe (the outside body of the refrigerator held hot / warm and freezer room temperature starts to cool ....? Means damage to the liquefaction component parts such as refrigerator heater, thermo / thermal fuse or defrost timer defective fridge. one by one with the following steps.

How to check the refrigerator heater

Step check on the component of the 2-door refrigerator that heater defrost the refrigerator in the following way:- See directly whether the heater is broken or the wire heater is broken.

- Using multi to check, if it is still good will connect and show the value of certain obstacles.

- Trying directly by connecting the two cables to the electric current, but if it is too complicated to check whether or not the heater and the thermal fuse you can try by combining both thermo defrost cable and turn the defrost timer into the liquefaction process position of ice where the engine compressor and motor dynamo fan will die and only heater that works to heat the ice in the evaporator pipe room to melt

How to check the 2-door refrigerator fridge timer

On checking the heater above mentioned is combining both thermo defrost cable, but to check the timer defrost refrigerator by splitting thermo defrost cable or reinstalling thermo defrost that is not cold conditions, because thermo defrost at cold time that temperature below 13 ° Celcius will be connected. |

| Location of transparent glass for gear check |

How To Repair 2 Door Refrigerator Do Not Less Cold

Two-door refrigerator is less cold there are many possible causes, namely:- The door is not tight can be the cause of the refrigerator is less cold.

- If the refrigerator with the model using the fan motor in the cooling section to cool or dispose of heat condenser pipe and the damage to the fan motor or condenser pipe fins are covered with dust will cause the refrigerator is not cold maximum. These are often found in refrigerator type inverters, bok freezers and showcase coolers.

- There was an impasse on the plumbing from the ice liquefaction process at the evaporator leading to the water reservoir. The deadlock causes the heater to be inundated and unable to heat the ice flower in the evaporator pipe room causing the accumulation of ice flower and blocking the air circulation path, if the refrigerator uses a pipe heater then the water will flow through the air passage to the lower door space causing the airway cooling path down undisturbed.

- The process of liquefying ice every 7 hours once failed to occur due to damage to the liquefaction component of the ice so that there is accumulation of ice flower in the evaporator room located in freezer space covered by bulkhead and close all the air circulation in and out

- A breakdown of the constriction of freon gas pipelines, the freon gas stalemate and the pressure of the compressor engine to pump the reduced freon gas will cause the refrigerator to be less cold, the way to fix it I will discuss at the end of this posting.

How to fix the 2-door refrigerator due to the accumulation of ice flower in the evaporator room

Detects the damage that occurs in the 2-door refrigerator with the characteristic of the accumulation of ice flower in the evaporator pipe room if one of the guesses will reappear the ice flower in about 1-2 days, so that no mistake in the replacement of components can be as follows :The first step

Liquid ice flower attached and attached to the freezer chamber spaces to the evaporator room by using hair drayer (ice hair dryer) to melt and easy to open it.

Or by spraying water for a faster way by moving the fridge out of the house certainly not to flood 😃😃😃

If waiting for the liquid itself can take a full day even up to 2 days.

After the ice melts some or all of them open the cover by opening all the bolts and pull the seal with the pliers.

Liquid all the ice flower if there are still left while checking the water path that leads to the container behind the refrigerator whether dead end or not.

Step two

Looking for the location of thermo defrost, thermo defros is attached to the muffler pipe, but some are placed on the pipe fins of the evaporator or in the divider.

|

| Examples of thermo defrost / bimetal |

Third step

Checking the refrigerator heater defrost and thermo fuse by turning the timer defrost slowly toward the reverse clockwise until the compressor engine and blower fan motor die, wait for about 10 seconds for the glass heater and 3-5 minutes for the heater pipe then unplug the power and check the heater defrost whether hot or not, when the heat means still good and worth using.

Step four

Checking the defrost timer by uninstalling or removing the thermo defrost so that the cable is not connected, connect the district refrigerator while looking at the rotation of the timer wheel through the transparent glass as in the timer image above which I circled whether it is rotating or not, when rotating means that the defrost timer is still good and proper to wear, another way if there is no transparent glass then wait approximately 45 minutes long then the timer if it is still going to rotate and go to the cooling process of the engine compressor and motor fan life again.

If all is in good condition ie smooth water pipe line, heater and thermo fuse good, timer is also good then the next step to replace thermo defrost, because thermo defrost guessing is still worth wearing or already damaged a little difficult, there is water inside thermo defrost can cause damage when checking time by putting in place of low temperature (cold) is still good not necessarily when in use still good.

Step repair refrigerator leak, clog or oil much stuck in the pipe evaporator

To fix the leaky refrigerator of course by patching and refilling the gas again, while for the problem of freeze gas freon find and repair.Are repairs steps as easy as that ...?

Oh certainly not, if the origin of the results may be less than the maximum and will not be durable lasting.

For that how to fix it can be done in the following way as follows:

Prepare work tools to repair the piping system and gas refrigrant

- Weld pipe

- Cutter pipe (pipe cutter)

- Pliers flops

- Capillary pipe cutter

- Manifold and hose

- Vacuum machine

- Gas Freon (refrigrant)

- Liquid cleaning material (R11)

- Liquid cleaning material (methyl)

- Copper welding silver

- Las almunium (aluplatinum)

- Las pipe copper - iron pipe (brass)

- The propellant gas material (nitrogen, R22 or R32)

- Filling pipes

- Filter

- Capillary pipe

- Sandpaper (scrubbing paper)

- Green glue, glue iron (if you want to patch leakage use glue)

- Vacuum: remove the air in the system so that the system becomes vacuum.

- fLushing: removes all types of dirt from the system.

# the system is the installation of pipelines in refrigerators such as discharge pipes, condenser pipes, capillaries, evaporator pipes and suction pipes.

Steps Repairing

Cut at the end of the gas filling pipe located in the compressor machine to know more clearly the type of damage, if after cut no gas exit or just a little means cause damage because there is a leak. When at the time of cutting the filling pipe a lot of gas out, meaning the cause of damage because the gas path is disrupted (dead end).

The first step by flushing the piping system

How to flushing on cooling system Freezer / Refrigerator / Showcase / Chiller (refrigerator pipe)

- Remove the discharge pipe and the end of the condenser pipe attached to the filter.

Plug the filling pipe with the weld on the discharge pipe function to insert cleaning fluid materials such as R11 or methyl then push with the pushing gas as you open the cap of the condenser until the water vapor out and make sure it is clean of any kind of dirt,

Flushing condenser is complete.

- Remove the suction pipe (suction end compressor pipe)

Cut the capillary pipe at the end of the filter and connect with the extended filling pipe to accommodate the cleaning fluid and push it with the pushing gas and the suction pipe ends open the lid until the vapor exits, when the evaporator pipe leaks , while pasted previously rubbed or painted in the sand around the leak until clean. But if you want to weld the leak sealed temporarily by hand.

For a dead end problem in the capillary pipe when it can not be cleaned with a cleaning fluid, it is best to replace it with a new capillary pipe.

Flushing evaporator is complete.

- To replace the capillaries is a bit difficult, but you can remove the capillaries from the evaporator and make the path with a hole backward with a screwdriver first to be able to know when there is a condenser pipe that is embedded behind the body of the refrigerator. Can also capillary pipes passed through the water channel.

- leak welds on the evaporator using aluplatinum previously cleaned from paint and oil.

- Rebuild the system

- Replace the filter with a new one.

- Change the compressor oil.

- Apply a 10 cm long vacuum capillary pipe on the filter beside the system capillary tube to use the refrigerator's built-in vacuum compressor

How to Vacuum on Freezer Cooler System / Refrigerator / Showcase / Chiller (Refrigerator)

- give nepel filling on the filling pipe in the compressor, if the compressor is problematic replace the new one, this is also like how to replace the compressor cooler, plug the hose with manifold and gas freon (refrigrant)Vacuum using a vacuum machine, if it does not have a vacuum machine, turn on the compressor while checking the vacuum capillary pipe will release air in the pipeline installation system until air is completely out of the vacuum capillary pipe.

- When the vacuum conditions, turn off the compressor while giving a little liquid methil at the end of the vacuum pipe, methil will be sucked in and directly push the tip of the vacuum capillary pipe.

Wait a few moments until there is no leak.

- Fill gas freon (refrigrant) to 40 psi and wait a moment, then turn on the compressor. On the needle of manifold will drop to 0 psi or less, if less gradually added until the contents of freon gas pressurized about 10 psi.

How to add freon gas must be patient and do not rush while looking at the evaporator pipe ice flower happening evenly.

- Normal charging time can take about 1 hour because gas filling should not be forced to full direct which result in too heavy compressor machine work.

- If there is already a flower of ice evenly in all evaporator and gas contents show 10 psi means refrigrant gas refill already finished. Push the filling pipe and then cut and clog the pipe with Las. The gas filling process has been completed.

Keep in mind:

If there is still a gemricic sound in the evaporator pipe and there is no ice flower, the flushing evaporator may not be clean from the oil or even the cleaning fluid is still in the evaporator pipe.

Similarly how to repair any type of damage to the refrigerator or other refrigerators.

Posting Komentar untuk "Refrigerator Repair Screts For All Interruption Of Damage"